Insights from the CEO of a billion-dollar revenue business who leveraged the procurement playbook to deliver >10% savings

Background

Mr. Elliot Zimmer was onboarded by the PE investors of Oregon Tool to turnaround the business performance. As part of his turnaround strategy, Mr Zimmer deployed a procurement improvement workstream focussed on improving margins across the vended finished goods.

Oregon Tool sourced these goods from >200 suppliers spread across >15 countries across USA, Europe, and Asia. The project addressed >30 diverse product categories in the forestry, and lawn & garden space including grinders, files, trimmers, trimmer lines, oil and lubricants, protective clothing, and engine maintenance parts.

Mr. Zimmer, an ex-consultant himself, is no stranger to executing procurement playbook by coupling inhouse procurement teams with external consultancy. PE backed portfolio companies often leverage this option because of its low risk, high-ROI, minimal capital commitment profile.

In this rapid interview, we asked him three questions to capture his perspective on the programme, and to capture his learnings around the critical success factors that he would like to share with other business leaders considering similar interventions.

Q&A

1. What were the challenges that Oregon Tool was facing, when you decided to seek external consultancy support?

The business was a bit in disarray as we were changing strategies. The strategy put in place about three years back had run its course, and we were financially under stress. Also, going through COVID, the organization had lost a lot of legacy knowledge. And with this background, the challenge was lack of understanding of how vended products played a role for Oregon Tool, in both its top line, as well as what we were spending on and how we were managing the suppliers for vended products. While there were some pockets of excellence across the sourcing team, overall, improvement was required to understand the core of our business, our spend, our supply base, or really how it fits with our business strategy.

You came as a referral from our PE investors. But as impressive beyond just the referral, you were doing some work with us and Tarun, you specifically came into my office and you weren’t rude about it, but you also didn’t take no for an answer. You got to my office, got on my whiteboard and quickly laid out the kind of the structure that I was used to seeing when you frame up what we spend our money on, where it comes from, and then how you go out about the approach to really control that spend and begin to manage that spend. So, I could tell very, very quickly that you all understood what good looks like when it comes to delivering strong procurement.

2. Great, and did the programme deliver in line with the expectations?

We delivered on three fronts. One, we saved money right away. Secondly, it essentially sent a message around the world to our supply base that Oregon Tool was back. And we started negotiating with confidence and really understanding our business. And then three, it made the entire organization cross-functionally understand our business much better.

As we defined our product strategy around what was core and not core, we were able to confidently exit certain categories and then other categories, we were able to kind of double down on our strategies and make sure that we were kind of strong between product management and sourcing, so on and so forth.

Some of that work still lives to this day. We’re still on track to save millions of dollars in vended finished goods as the team continues to work through the next wave of opportunities, but now the team know our suppliers a lot better, and have a plan on what needs to be done to gain leverage, and to continue to drive value through sourcing.

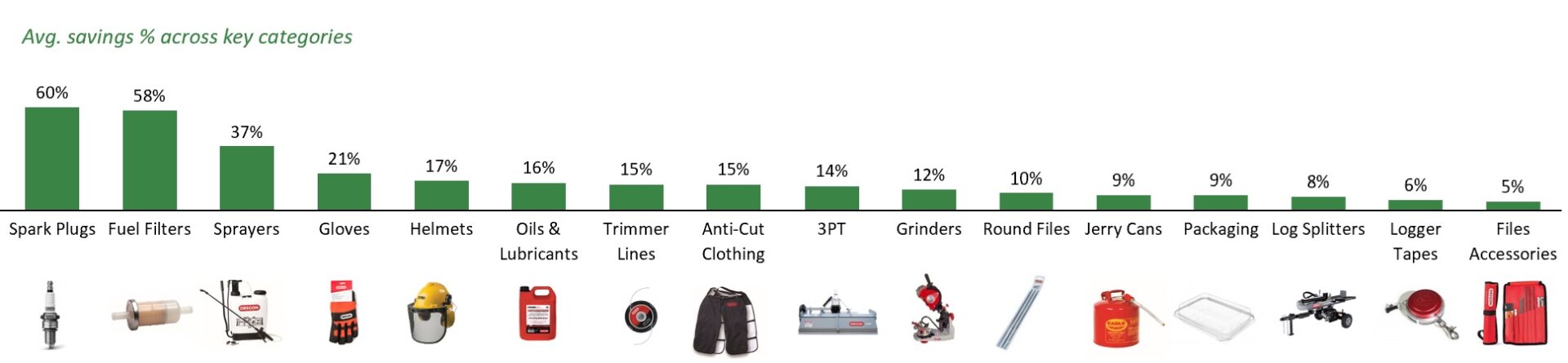

Figure 1: Results overview- Savings of up to 60% achieved on categories. In majority of the cases, final result of the exercise involved staying with the incumbent.

3. For other senior leaders facing similar challenges, what advise would you give on the critical success factors while undertaking a similar programme?

Number one, don’t be afraid to go fast. In many instances, internal teams may suggest a lot of logical reasons why it takes another month, and another month to understand the spend and analyse the opportunities. You will hear why the systems aren’t there and the data’s not there, so you need more time and everybody just bogs down waiting to get started.

Don’t be afraid to start with 80% correct information and then iterate in due course.

Get a sense of what the spend is, grab it from finance, grab it from wherever you can right away, and lay a hypothesis on the table and get started as fast as you possibly can.

When we got into it, I called you all and gave you 48 hours to sit down and figure out what we would do. We walked into the investors office, and committed to get X percent of spend out across this major category.

I knew when we did that, that in 48 hours we didn’t have it all perfectly laid out, but I liked the willingness to put a hypothesis on the table and dive in with both feet.

Number two, keep the executive sponsorship in place. This is not something to be outsourced to or delegated to the director of procurement or name the person in your organization. Noise is going to come when you are bringing in a consultancy to drive fundamental change and value creation as fast as possible.

You’ll hear the organization say, oh, their data’s not right, or, I don’t know where they came up with that, or, they’re going to burn down the house because they’re too aggressive. In my opinion, you don’t want to spend money on a consultancy to just have people camped out in your business looking at data and telling you to improve processes.

If you outsource the sponsorship, then what will inevitably happen is that the project will lose steam for all those reasons that I kind of started with and then you’re stuck.

But once you empower the consulting team and give them the latitude to run hard, then you can do great things internally and externally with suppliers that are going to push back or internally with cross-functional teams that you’re putting a little bit of pressure on.

Number three, be cognizant of that real kind of team building dynamic as this is the ultimate team sport. It’s going to take product management. It’s going to take engineering. It’s going to take sourcing. It’s going to take salespeople that need to be willing to make trade-offs. And it’s not for the faint of heart when you’ve got a big supplier who’s threatening to pull their business from you.

And so you need to keep the team really engaged as you go, and also keep celebrating the successes along the way. Throughout the programme journey, we reminded the team on the wins by respective members, sent notes recognizing their wins, which really kind of helped reinforce to the organization that this was important and this is how you could grow your career at Oregon Tool.

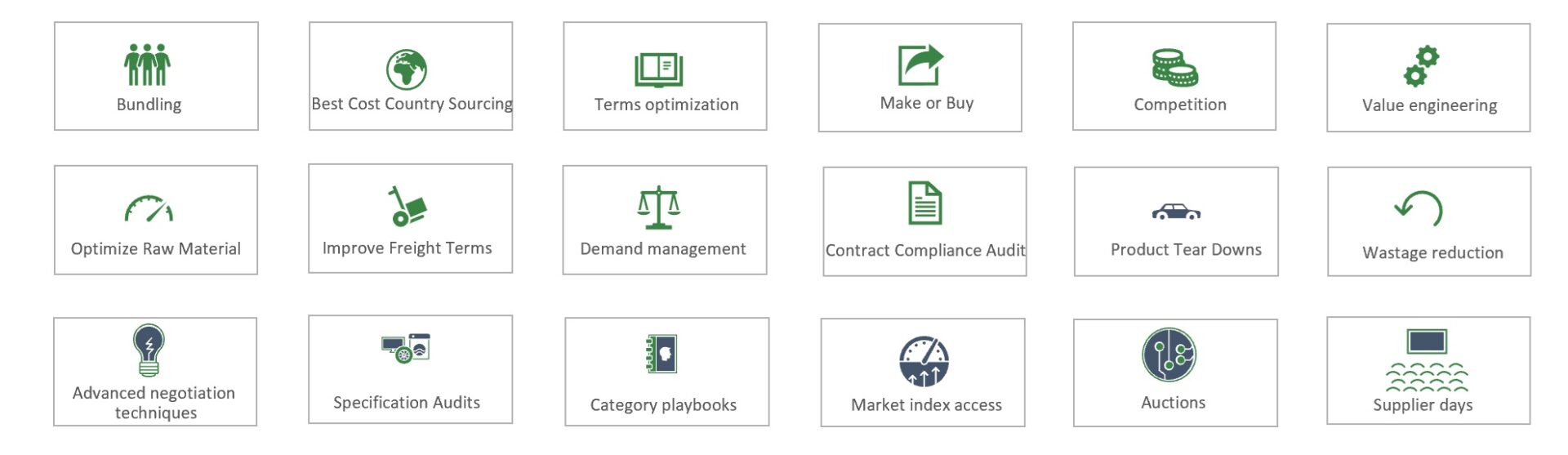

And finally, keep in mind that the value is unlocked through multiple levers and it’s not a case of one size fits all. A lot of sourcing consultancies tend to be one-trick ponies. They want to push a system or they want to tell you to do a reverse RFP process and so on. With Enabling team, we leveraged multiple plays at any given time. In some cases, we were moving the business to new suppliers. In other cases, we were negotiating. And in other cases, we were consolidating.

Figure 2: Levers typically deployed in Enabling Procurement approach.

— End of Interview —

About Oregon Tool

Oregon Tool is a global, premium-branded, aftermarket-driven precision-cutting-tool powerhouse platform. The company’s portfolio of brands specializes in professional grade precision cutting tools for forestry, lawn and garden; farm, ranch and agriculture; and concrete cutting and finishing.

Headquartered in Portland, Oregon, with a multinational manufacturing and distribution footprint, Oregon Tool sells its products in more than 110 countries under the Oregon®, Woods®, ICS®, Pentruder®, Merit®, and Carlton® brands.

The company is the world’s #1 manufacturer of saw chain and guide bars for chainsaws and diamond saw chain for concrete and pipe, a leading manufacturer of agricultural tractor attachments, and the leading OEM supplier of first-fit and replacement parts.

About Mr. Elliot Zimmer

Mr. Zimmer brings more than 20 years of experience working in a variety of leadership roles at Lennox International, Dr. Pepper Snapple, McKinsey & Company, and in the United States Army. He has a BS in Systems Engineering from West Point and an MBA from Harvard Business School.

If as a senior leader in the business, you are looking to leverage the procurement playbook to generate impact with speed, and would like to discuss how we can support you, don’t hesitate to get in touch!